Apple Pushes Suppliers to Embrace Robotics

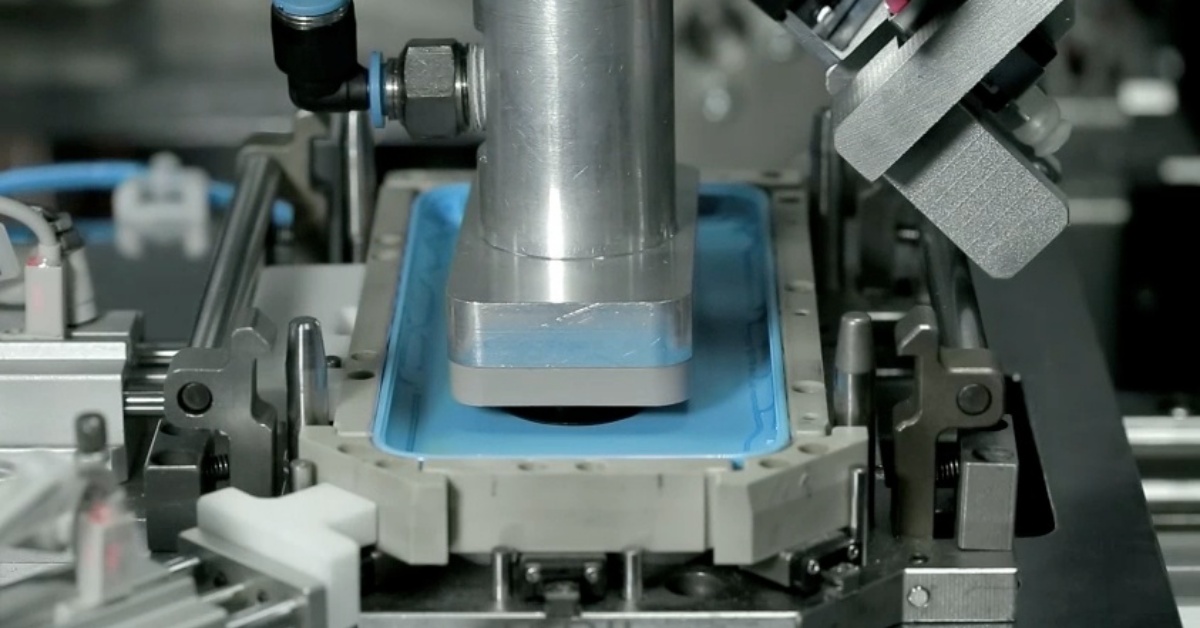

Apple is requiring suppliers to adopt robotics in manufacturing, shifting costs onto partners while aiming for consistency, lower labor reliance, and supply chain flexibility beyond China.

- Apple Enforces Mandatory Robotics Adoption for Suppliers: Apple now requires its suppliers to integrate robotics and automation in their factories as a strict condition for future contracts, shifting from encouragement to compliance.

- Cost-Sharing Shift in Production Equipment Investment: Instead of funding manufacturing equipment upfront, Apple is asking its suppliers to finance their own robotic systems, which increases financial pressure on partners.

- Advantages of Automation for Apple: Robots help Apple reduce labor needs, improve product consistency across factories worldwide, stabilize costs, and mitigate risks from global disruptions like pandemics.

- Global and Standardized Manufacturing Processes: Apple aims to implement uniform robotic systems across different countries to ensure consistent product quality, supporting its strategy to diversify beyond Chinese manufacturing.

- Strategic Move Toward U.S. Manufacturing and Geopolitical Flexibility: Automation enables Apple to shift production geographically more easily, potentially facilitating future U.S. assembly of iPhones and reducing reliance on China amid geopolitical tensions.

Apple is turning up the pressure on its supply chain. According to a new DigiTimes report, the company now requires suppliers to adopt robotics and automation in their factories, or risk losing future contracts. What was once encouragement has become a hard rule.

Why Apple Wants Robots Now

For years, Apple has invested heavily in equipment for its manufacturing partners. That approach is changing. Instead of footing the bill, Apple is now asking suppliers to fund their own robotic systems. This move is putting financial strain on some partners, who face high upfront costs and potential disruptions while switching to automated production.

But Apple sees big advantages. Robots cut down on labor needs, improve consistency across factories in different countries, and help stabilize costs long-term. They also provide insurance against global events, like COVID-19 restrictions, that exposed the risks of relying on large human workforces.

A Shift in the Supply Chain

This mandate isn’t limited to one product. From iPhones and iPads to Macs and Apple Watches, Apple wants automation across the board. Standardized robotics mean that whether a device is made in China, India, or elsewhere, the results will look the same. That consistency is crucial as Apple continues to spread production across multiple countries to reduce dependency on China.

Suppliers, however, are feeling the pinch. With no subsidies from Apple, margins are taking a hit. The upfront investments are steep, and the transition period brings added challenges.

Bigger Picture: Beyond China and Into the U.S.?

Apple’s push for automation also ties back to geopolitics. The U.S.-China trade war pushed Apple to diversify its supply chain, leading to expanded operations in countries like India. By making robotics the baseline, Apple can more easily shift production wherever it needs to without worrying about labor availability or cost.

Some even see this as laying the groundwork for iPhones to one day be assembled in the United States. Apple reportedly told U.S. officials years ago that “robotic arms” would be essential if iPhone manufacturing were to move stateside. With more automation in place, that idea may not be as far-fetched as it once seemed.

Written by

Ravi Teja KNTSI’ve been writing about tech for over 5 years, with 1000+ articles published so far. From iPhones and MacBooks to Android phones and AI tools, I’ve always enjoyed turning complicated features into simple, jargon-free guides. Recently, I switched sides and joined the Apple camp. Whether you want to try out new features, catch up on the latest news, or tweak your Apple devices, I’m here to help you get the most out of your tech.

View all posts →More from News

WhatsApp Begins Global Rollout of Promoted Channels and Status Ads

WhatsApp is rolling out Status ads and Promoted Channels globally, adding ads to the Updates tab while keeping private chats encrypted and unchanged.

IDC: iPhone Could Gain Share in 2026 as Memory Shortage Hits Android

IDC forecasts a 12.9% smartphone market decline in 2026 due to a memory chip shortage, with budget Android devices hit harder than iPhones.

Apple Maps Adds Detailed 3D Formula 1 Track Guides Ahead of 2026 Season

Apple has updated Apple Maps with detailed 3D renderings of Formula 1 circuits ahead of the 2026 season, beginning with the Australian Grand Prix at Albert Park and expanding to tracks across the full 24-race calendar.